The U.S. Department of Commerce's announcement of export control measures against ZTE Corporation has sparked nationwide attention to domestic chips.

According to statistics, China's integrated circuit imports have exceeded $200 billion annually for many consecutive years. One can imagine the production difficulties that would arise in the event of a "chip" shortage.

So why are "chips" so important? Where are the shortcomings in China's chip manufacturing industry? When will we achieve genuine "Chinese chips, made in China"? Today, let's briefly discuss China's chip manufacturing industry.

Are chips, integrated circuits, and semiconductors the same thing?

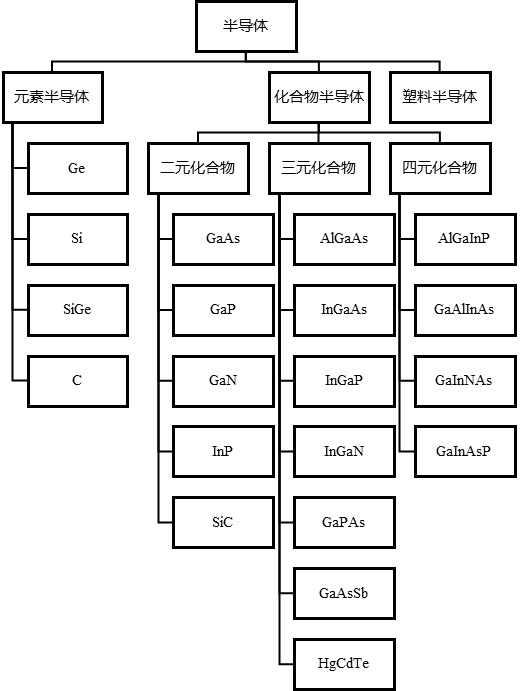

We often encounter terms like "chips," "integrated circuits," and "semiconductors." These words are frequently used interchangeably in everyday discussions. If a distinction must be made, integrated circuits can be considered a broader concept.

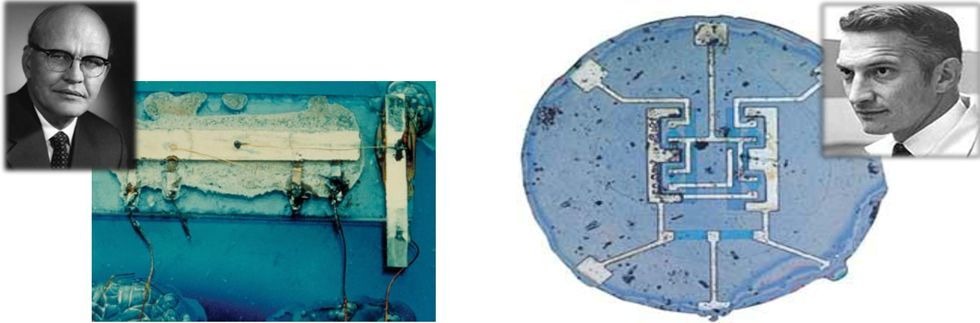

On September 12, 1958, Jack Kilby, an engineer at Texas Instruments in the United States, invented the theoretical model of the integrated circuit. In 1959, Bob Noyce, who had studied under one of the transistor inventors, William Shockley, pioneered the mask exposure etching method and invented today's integrated circuit technology.

What we refer to as integrated circuits involves using specific manufacturing processes to integrate transistors, resistors, capacitors, inductors, and the connections between them—all required for a circuit—onto a small silicon-based semiconductor wafer, which is then encapsulated in a housing to form a microdevice with the desired functionality. In national industrial statistics, integrated circuits are often used as a broad concept.

A chip refers to the semiconductor substrate (most commonly a silicon wafer) containing integrated circuits and serves as the physical carrier of integrated circuits. Semiconductors are materials with conductivity between conductors and insulators, such as silicon, germanium, and gallium arsenide, used in chip manufacturing.

The integrated circuit industry is both close to and distant from ordinary people. Most only know that electronic devices are used in mobile phones, computers, and various industries—chips are essential for CPUs, GPUs, microcontrollers, CNC equipment, and automobiles. However, only a few understand chip design and manufacturing.

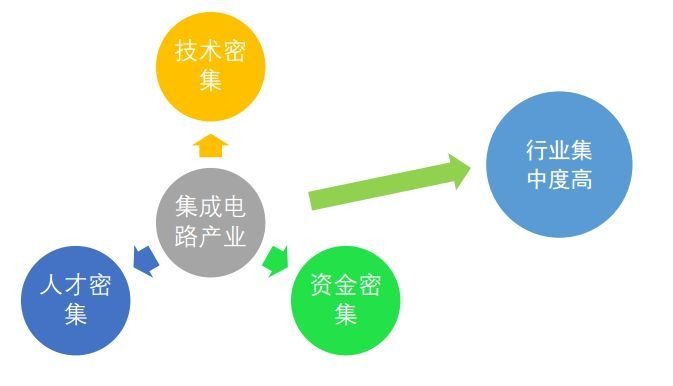

The chip industry is highly technology-intensive. Many may never have heard of chip manufacturing "jargon" like PCB layout, wafers, tape-outs, processes, packaging, and lithography. Additionally, the chip industry is extremely capital-intensive, with production lines often costing billions or tens of billions of dollars. Talent is also a scarce resource in this industry. On one hand, the technology is expensive and difficult, making talent hard to cultivate. On the other hand, the industry is highly concentrated, with a few major companies monopolizing cutting-edge technology and markets, making it difficult for remaining companies to match the compensation offered by these giants.

Carving on a wafer the size of a fingernail, a chip is born.

Chip production is a process of turning sand into gold, with value density skyrocketing from sand to wafers to chips. The actual chip manufacturing process is highly complex. Below, we provide a brief introduction.

A wafer refers to the silicon wafer used in the production of silicon semiconductor integrated circuits. Because of its circular shape, it is called a wafer. The value from wafer to chip alone can increase twelvefold. A wafer raw material worth ¥2,000, after processing, yields finished products worth approximately ¥25,000—enough to buy a high-performance computer.

Pulling wafers from molten silicon and slicing them.

After obtaining the wafer, a photosensitive material is evenly applied to it. A lithography machine is used to transfer complex circuit patterns onto the photosensitive material. The exposed areas dissolve and are washed away with water, exposing the intricate circuit structures on the wafer surface. An etching machine is then used to etch away the exposed parts of the silicon wafer.

After polishing the wafer, a lithography machine transfers the designed circuits onto the wafer.

Etching complex structures onto the wafer.

Next, after hundreds of complex processes such as ion implantation, these intricate structures acquire specific semiconductor properties, enabling the creation of hundreds of millions of functional transistors within a few square centimeters.

After copper plating, excess surface copper is removed.

Covering with copper as interconnects links the hundreds of millions of transistors.

After testing, dicing, and packaging, we obtain the chips we see.

After months of processing a wafer, integrating kilometers of interconnects and hundreds of millions of transistor devices into a space the size of a fingernail, qualified chips are diced out, and the remaining parts are discarded. After rigorous selection, a genuine chip is born.

Discarded wafer after dicing out qualified chips.

Lithography machine precision: the bottleneck in chip manufacturing.

Four major factors constrain the development of integrated circuit technology: power consumption, process, cost, and design complexity. Among these, lithography machines are a top priority—the core of core technologies.

Some equipment is hailed as the "jewel in the crown of industry" due to its immense manufacturing difficulty. The most mainstream view points to two types of equipment: aircraft engines and lithography machines. The most advanced aircraft engines currently cost tens of millions of dollars, while the most advanced lithography machines now exceed hundreds of millions of dollars.

The integration level of chips depends on the precision of lithography machines. Lithography machines need to achieve image resolutions of tens of nanometers or even higher. The higher the precision of the two core systems of a lithography machine—the optical system and the alignment system—the finer the grooves that can be etched on silicon wafers, leading to higher integration and greater computing power.

Currently, a Dutch company holds 80% of the global lithography machine market and monopolizes high-end lithography machines. China is striving to catch up but still lags behind foreign technology by generations—two generations behind the U.S. and one generation behind U.S. allies. However, this does not mean our efforts are unimportant. If we don't develop our own, foreign companies can sell as they wish—whether to sell, which models to sell, and at what prices would be out of our control. Once we develop our own, foreign companies will sell us higher-precision equipment at more reasonable prices.

AMD's chip manufacturing documentary.

At what level is China's chip manufacturing?

Overall, China's chip manufacturing technology is developing rapidly, but issues remain, such as lagging processes, insufficient capacity, and talent shortages.

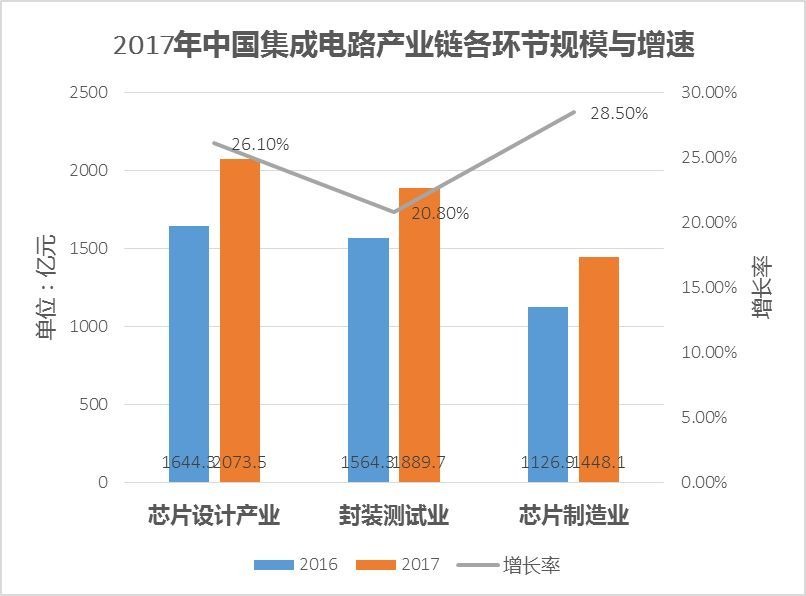

China's integrated circuit industry is divided into three parts: chip packaging, design, and manufacturing, all showing rapid growth. From 2004 to 2017, the average annual growth rate was close to 20%. Between 2010 and 2017, the compound annual growth rate reached 20.82%, while globally it was only 3%–5% during the same period.

However, on the other hand, China's integrated circuit manufacturing process lags behind international peers by two generations. It is expected that by January 2019, China could achieve 14-nanometer product manufacturing, while foreign counterparts could achieve 7-nanometer product manufacturing. Capacity is severely insufficient, with 50% of chips relying on imports. Additionally, there is a structural mismatch between China's capacity and demand—the products that can actually be produced do not meet market needs. Long-term foundry models have led to a mismatch between design and manufacturing capabilities and a lack of core technologies. Issues such as chaotic investment, insufficient R&D investment, and talent shortages mean that China's integrated circuit industry is still in a state where "core technologies are controlled by others, and products are mid- to low-end," a situation unlikely to change fundamentally for a long time.

More specifically, in digital circuit chip design, we can still catch up by imitating, but in analog circuits, the accuracy of products like crystal oscillators and AD acquisition cards is not yet high enough, accumulation is insufficient, and core technologies are not yet in our hands.

Although China's chip industry is still relatively backward overall, this does not prevent us from manufacturing our own chips in specific application scenarios.

Two examples: mobile phone chips and the underlying computing chips used for "mining" in the emerging blockchain technology.

In the wave of mobile internet, Chinese companies early on介入 mobile phone chip R&D, securing a place in the mobile phone application scenario.

In today's booming blockchain technology, mining machine-specific chips are基本上 monopolized by Chinese products. Mining chips initially used普通 computer CPUs, then GPUs and FPGA chips. Later, Chinese entrepreneurs removed unnecessary components to create chips专门 for mining, maximizing算力 and energy efficiency. Coupled with China's强大的基础制造体系, they monopolized this emerging market.

In today's traditional chip领域 dominated by giants, some application-specific chips are key for China to achieve弯道超车 in the future. Besides the aforementioned mobile phone and mining machine chips, there are also AI chips专门 for artificial intelligence computing, etc.

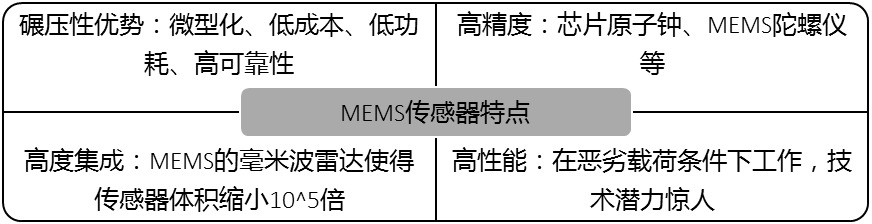

Traditional chips mostly involve drawing two-dimensional circuits on silicon wafers. With the rise of IoT technology, the interconnection of everything poses巨大的需求 for sensor technology. A new technology called "MEMS" (Micro-Electro-Mechanical Systems), which雕刻 three-dimensional mechanical structures on silicon wafers, is gradually gaining attention.

MEMS accelerometer.

Compared to traditional sensors, MEMS sensors have a dimensionality advantage. MEMS-made gyroscopes, microphones, pressure sensors, etc., are used in missiles, mobile phones, and wearable devices, playing significant roles.

Currently, the MEMS field is experiencing rapid growth of 200%–300% annually. China's research in this field is at the forefront globally.

Conclusion

Chip manufacturing is an industry highly dependent on technology, capital, and talent, especially in processes where lithography machine precision is the关键中的关键. In today's traditional chip领域 dominated by international giants, some emerging chip fields are important突破口 for China to achieve弯道超车, and China has already secured a place.

The recent ZTE incident also conveys to the public this reality: the domestic replacement of chips is by no means optional. While it cannot be rushed, it must be accelerated.

Hot News

Hot News